FULL SERVICE

Ethical Labor & Sustainable Production

Production with No MOQ

With no minimums, we make on-demand production possible.

Prevent overstocked products and avoid unsold clothing, making your business more sustainable.

Personal Assistance

If you have any questions please don’t hesitate to ask, we’re committed to making your job easier.

We will also help you find all materials needed - just ask your dedicated order manager!

Quick Lead Times

We get it: Every order is urgent.

Our lead time in fulfilling most sample orders is 2-3 weeks, production up to 6 weeks.

How to Work with Us

Consult Us

Send tech-pack with specs & details or reference sample with directions for alteration.

Purchase Services

Purchase your pattern & sample, PayPal invoice will be issued accordingly.

Keep Updated

Order and send fabric from SwathOn or request free sourcing.

Receive Goods

Confirm sample photos via email and recieve parcel within 3 weeks.

Seamless Production

Quality Control

We thoroughly inspect every garment to detect any defects before shipment. We guarantee zero-faulty productions.

Direct to your Door

Safe door-to-door Air Express delivery. Save time and cost by directly shipping to your doorsteps.

Easy Importing

We prepare all the custom forms and documents you need so that clearing your shipment through customs is seamless.

Spec-Sheets

Your tech-pack is a blueprint you’ll use to communicate your design.Please feel free to utilize our spec-sheets.

It should contain your technical sketches, bill of materials with colorways, garment measurements and construction details.

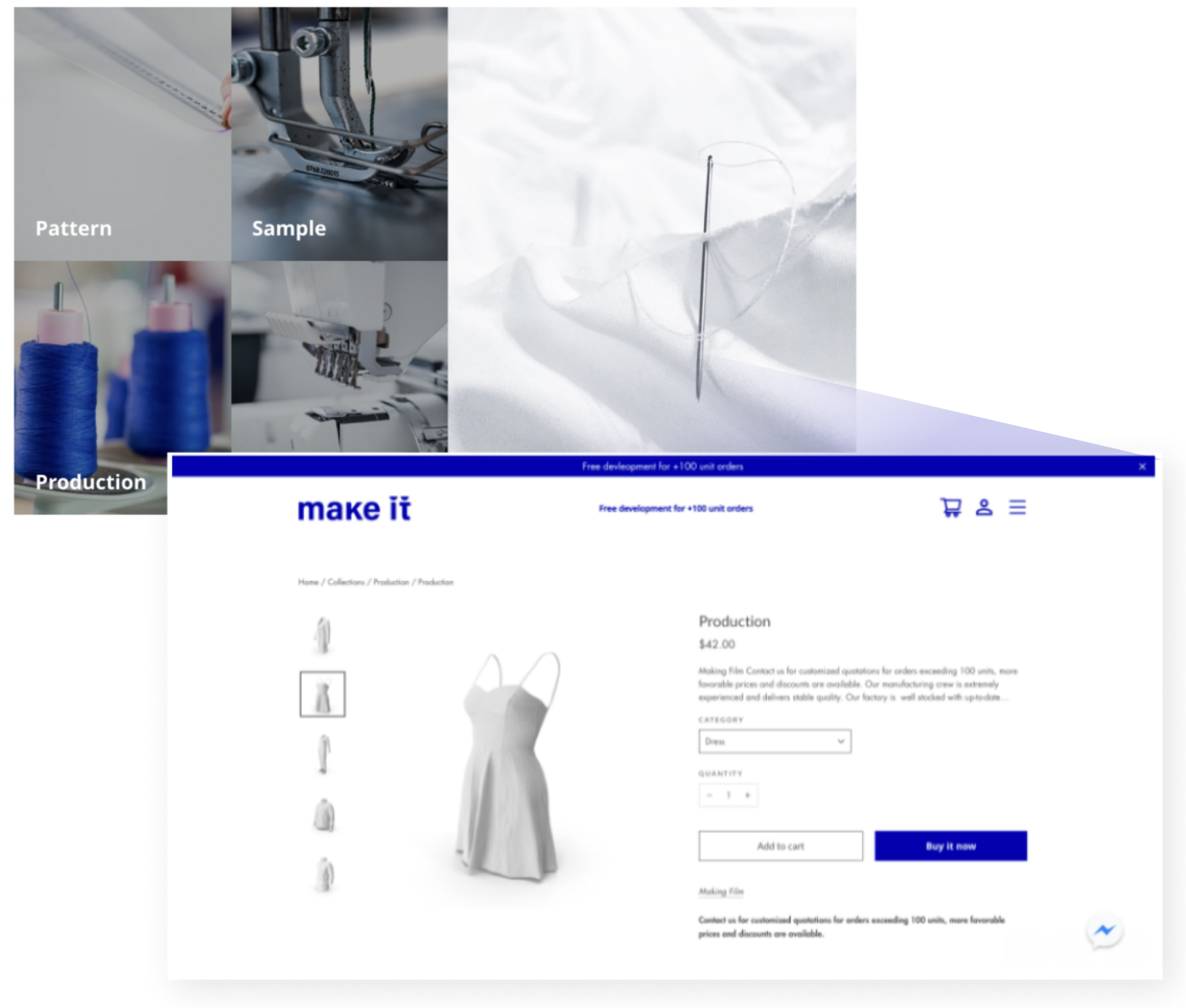

development cost refund

Production +100 units

Skilled Development, Production with No MOQ, Inspection with ZERO Faulty, Customized Print & Embroidery and Labels & Tags - Everything you need

Productions

Zero Faulty

We keep excellent track of fit & construction and all samples will be confirmed via email before shipping out.

We also inspect every item we ship out to ensure satisfaction at your customers end.

Quality is not an issue when working with us.

Customer Reviews

![]() Tuckernuck Sports

Tuckernuck SportsDesigner, US

Your cost and development sample were the reasons we recommended to move this style to your factory, knowing that our supervisor sees this as an ongoing style for future seasons. We appreciate you working hard to make this transition a success.

![]() Novu Collection

Novu CollectionFounder & Owner, UK

The ease of communication and development capabilities is just AMAZING! Our account manager simply “gets” our aesthetics and suggests styles and constructions to produce hit items.

![]() Storm Label

Storm LabelFounder & Owner, UK

I’ve worked with Make It from the very start, and owe my success to them. Their expertise in fashion manufacturing has provided a way more supportive role than a simple supplier.

![]() Renwick

RenwickDesigner, US

Thank you for the spec-sheets and prototype photos coming to me ahead of time. You are one of my most favorite facilities to partner with and I want to make sure our business can continue successfully for both of us!

![]() Eufori

EuforiFounder & Owner, AU

Had great reviews on the all items, very happy customers, thank you! Sales have started to go really well, so I'll be placing another order in 2-3 months time. Couldn't have done it without your team.

![]() Krill

KrillFounder & Creative Director, US

I am new to this process, so thank you for your patience and guidance in providing tips. I really appreciate it. Your team is great and I am very impressed with the quality and craftsmanship.

![]() MuskOx

MuskOxDesigner, US

Thank you! We expect to place a purchase order for multiple items as soon as I have the swatches on hand. We are going to plan for all of the developed styles for early fall. The fit and construction is GREAT!

Eden Design

Customized woven labels & hang tags are essential in branding your business. Work with the best, our partner Eden Design. Choose from a wide variety of categories, including packaging materials.

SwatchOn

Where do you source your fabric?

Did we mention our collaboration with Swatch On, wholesale fabric platform that has more than 200,000+ products online. Address your fabric to Make It, get free shipping and faster lead time.

Buja Market

Sourcing is a hard, yet an essential part of development. That's why we teamed up with Buja Market, a Korean domestic app with AI image search. Send us photos of all materials needed, and we’ll search & source for you.

Blog Posts

It can be difficult keeping up with all of the rules and regulations involved in importing clothes to the U.S. Find out five simple rules to make your bulk imports successful. Clothing - almost every human being on the planet wears some form of it. As an import industry in the United States, it brings in over $80 billion annually. Knowing the regulations for how to import clothes to the U.S. can help you navigate the process successfully. Importing clothing and apparel into the U.S. requires compliance with multiple government agencies. These agencies include the Federal Trade Commission (FTC), the Consumer Product Safety Commission (CPSC), and the Environmental Protection Agency (EPA). Labeling laws should be reviewed for compliance with various regulations. Our guide below details five rules for importing clothing and apparel to the U.S. that will help you avoid heavy penalties and delays. Frequently the most popular of U.S. imports, clothing and apparel are a big deal in the international trade industry. Keeping up with the demand for various styles, materials, and accessories requires carefully navigating a lengthy list of rules. It is also a good idea to familiarize yourself with the nations that the U.S. frequently imports clothing from. China, Vietnam, and India account for over half of the total value of imports. When choosing manufacturers in these countries, it is important to be sure they are up to U.S. standards. 1. Know the Agencies that Oversee Compliance All imports must be inspected and approved by the U.S. Customs and Border Protection (CBP) agency when arriving at a port of entry. For clothing and textile imports, the CBP works together with a number of other government agencies to ensure compliance for labeling, materials, and more. One or more of the following agencies may likely need to be addressed when completing your shipping documentation. Federal Trade Commission (FTC): Sets and enforces rules for labeling various materials, using care instruction labels, and listing correct nation of origin. Consumer Product Safety Commission (CPSC): Maintains mandatory standards for flammability of all clothing and in particular for children’s sleepwear. CPSC has the authority to order destruction of shipments found to be out of compliance. Environmental Protection Agency (EPA): Sets standards for coating and dyeing of textiles and clothing Meeting all the requirements set by supervising government agencies is one way to improve the chances your shipment clears customs quickly and efficiently. 2. Follow the Care Labeling Rule The Care Labeling Rule was created by the FTC to ensure that imported or domestically manufactured clothing contained a label detailing regular care instructions. The label may include information on whether garments are machine washable or must be dry cleaned. The label must also include any warnings such as ‘Do not iron’ if such an action would damage the item. Some textile apparel and accessories are exempt from this rule, such as: Shoes Gloves Hats Handkerchiefs Belts Suspenders Neckties One-time use garments of non-woven material Although you can import items that don’t have a care label included, the clothing cannot be sold until such a label is attached. Labels should be permanently attached, so it may be best to find a supplier or manufacturer who will do this before shipping. The FTC will fine each individual garment that is found to be missing a label or containing a label with inaccurate information. Finding a trustworthy supplier or manufacturer is therefore crucial. 3. Meet the Marking Requirements for Apparel The marking requirements apply to wearable apparel and are separate from the FTC’s Care Labeling Rule. Marking requirements are set up by the CBP to be in compliance with the North American Free Trade Agreement Implementation Act (Mod Act). The Mod Act makes sure that the CBP provides the trade community with clearly defined information and rules for the importing process. Their guidebook, available from the CBP, details the requirements for information such as: Country of origin marking Textile fiber identification Wool product labeling The CBP’s marking requirements are extensive and while their guidebook provides excellent details, it is meant as a general guide only. Reaching out to a Licensed Customs Broker may be the best way to be sure you are satisfying all related factors affecting import. Experienced brokers may assist on proper classifications of products to avoid fines and penalties. 4. Meet Mandatory Flammability Requirements Making sure clothing is safe and made from textiles that meet U.S. safety standards is good for businesses and their customers. When it comes to fire safety, the CPSC has strict regulations in place. They enforce regulations with the power of three different acts. Consumer Product Safety Act Flammable Fabrics Act Federal Hazardous Substances Act Any violations may result in not only fines, but in having your shipments destroyed in port on your dime. All clothing intended for everyday wear by adults or children has to meet the General Wearing Apparel Standard (16 C.F.R. Part 1610). The standard is used to rate the flammability of textile used in clothing and has three levels. Any textile identified as Class 3 cannot be used in clothing. While there are exceptions to the standard, it is best to have an experienced broker alongside to navigate the differences. 5. Find Your Correct Harmonized Tariff Schedule Finally, you want to make sure that import duty rates are being paid correctly to the CBP. Trade goods are classified through Harmonized Tariff Schedule codes. These HTC codes determine tariff rates for each product entering U.S. ports of entry. If you use the HTS code, the taxes you pay may be incorrect. Whether the amount you pay is higher or lower, fixing the mistake takes time and usually results in penalties. Mistaken HTS codes may also result in your shipments being exported out or destroyed. You might have complied with all the laws, but if your shipments were mislabeled it could cost you in lost merchandise. There are several different look up tools that allow you to search on your own, but this might be risky especially if you are new to the import business. Hiring a customs consultant may save you money in the long run. Work With Make It to Facilitate your Clothing Import Make a name for yourself in the fashion industry by being able to get your hands on great clothing. Let us help you do so in time to catch the next greatest trends. Meet with one of our experienced and seasoned managers in a 1-on-1 session and get guidance on everything from prototyping to bulk import. With expert help from Make It, your business can strut its way to new levels. Get a personalized quote today and see how Make It can become a part of your success story.

What is product sourcing? In business, the term refers to a number of procurement practices, aimed at finding, evaluating, and engaging suppliers of products. So, what exactly are these practices? In this white post, we’ll provide an in-depth look at the entire sourcing process – from sourcing to shipping – and walk you through, one step at a time. Read on to gain a clear picture of sourcing and better understand how all of the pieces fit together – and ensure the delivery of quality products to the end user. Sourcing Starts With an Agent and an Agenda What does a sourcing agent do? A sourcing agent assists companies with the process of locating sources for products and supplies at low prices so they can save money on production. Sourcing agents may represent a single company or could run a business that serves a number of companies. Domestically, a company can use a sourcing agent to get the best prices. Sourcing agents have connections with domestic companies and know where to find various supplies. They can negotiate with a prospective supplier and may be able to work out discounts and other deals that the company does not have time to negotiate on its own. This can save the company money and may also create a longstanding and valuable contract for the supplier, so both sides have an incentive to work with a sourcing agent. Key advantages of domestic sourcing include: Higher manufacturing quality and labor standards Easier communication with no language barrier Marketing appeal of being made in North America Easier to verify reputable manufacturers Faster shipping time High intellectual property right protection Greater payment security and recourse But, there are also some disadvantages to sourcing domestically, such as: Higher manufacturing costs Less product choice (There are many items that aren’t made in North America anymore) Companies may also have an interest in an overseas sourcing agent. In this case, they rely on the agent to locate companies they can work with overseas. The sourcing agent’s job includes assessing the needs of the company, locating suppliers, and meeting them to see if they will be able to take on the orders. They inspect factories to confirm that they will be able to meet standards. This can also include evaluations to address ethical concerns like worries about pollution or exploitative labor conditions. The advantages to sourcing overseas include: Lower manufacturing costs High number of manufacturers to choose from One-stop services have made it easy to navigate suppliers If there are issues with the quality of the product, it is much harder to address with a vendor through cultures, time zones, and geographies than if you are meeting with a local supplier. That’s why there are also disadvantages to sourcing overseas, like: Lower perceived quality from customers (Usually) lower manufacturing and labor standards Little intellectual property protection Language and communication barrier can be difficult to navigate Difficult/costly to verify manufacturer and visit on-site Longer shipping time Cultural differences in business practices Product importation and customs clearance Less payment security and recourse So, when starting the sourcing process, it’s essential that you firstly define what it is that you are looking for. When working with a sourcing agent, you need to know what type of supplier you want to work with. Having a clear direction will help in your research so that you’re able to find the right supplier. It’s also important to know what you should ask your supplier once you’ve found them. Does the supplier have a widget? Are their prices in your wheelhouse? Specifications need to be initially set to ensure you’ll get the product you want – made by the right manufacturer that will arrive to the end user appropriately. When working with a supplier, you should establish a clear joint commitment that includes: Identifying the best solutions Upholding quality and efficiency A unified approach – essential for delivering premium end-to-end solutions Rapid adoption of evolving technologies Access to new distribution channels A supplier engagement process After pinning down a solid plan, it’s time to dive into the process. Making it Happen: Sourcing Steps Let’s now take a walk through each step of the sourcing process: Make/Design/Buy Analysis First, you must analyze the following: Establish business cases to support decisions for products and services Analyze potential solution options Manage the preliminary buy assignment and ensure it is understood and accepted Structure and analyze information and input data Prepare sourcing activities RFX RFX is a catch-all term in strategic sourcing that captures all references to Request for Information (RFI), Request for Proposal (RFP), Request for Quote (RFQ), and Request for Bid (RFB). In this step, you will: Manage requests for information, proposal, and quotation Negotiate Achieve signed agreements with suppliers that fulfill your business requirements Implement agreement Register, archive, and communicate agreement data to relevant systems, stakeholders, and users Call Off Next is the call off, when you: Create orders to buy products or services Monitor delivery Post a goods receipt Submit a claim to supplier Invoice to Payment In this step, you will: Receive invoices manually or via electronic messages Process invoices and credit notes, including matching invoices with purchase orders and securing authorizations Pay supplier invoices Handle statement of accounts, reminders, and supplier account reconciliation Manage Production and Quality Production management focuses on upholding quality. Quality needs to be defined so that both the supplier and buyer understand and are in agreement. Defective products lead to unhappy customers, and have to be sold at a discount or written off entirely, further eroding your brand identity in that part of the world. A key part of an efficient supply chain is having a quality product all the way through it. After you’ve established what you want, devised a plan, figured out the logistics, and maintained quality management, you’ll have properly sourced with your customers’ best interests in mind! Key Takeaways Now that you better understand product sourcing and the necessary steps to ensuring quality along the way, you’ll know what to do, who to work with, how to find them, what to ask, and how to effectively plan and manage. When sourcing is done right, your customers receive the best – and that’s the core of what constitutes a successful business.

Price vs. Quality The products you create for your company are a representation of your brand. These products bring back customers and turn them into promoters of your business. So, why not have quality products? Why not create something that your customers can’t get enough of? Quality is fundamental in creating a successful business – but how do you create quality? Do you build quality into a product or can it just be inspected into a product? And, does price define quality? In this white paper, we’ll answer these questions, offer an in-depth comparison of price to quality, and explain what both terms really mean in the manufacturing world. Read on to learn what it takes to a build a top-of-the-line business. How to Define Quality Quality is defined as products and services that deliver intended performance. The strategic goals of most manufacturing companies include manufacturing competitive products, operating profitably, and growing their business in an environment of increasing globalization and elevated product development costs. In order to accomplish these goals, factories need to distribute quality products. So, what does that really mean? When measuring quality, factory managers identify the intended function of the product in order to meet customer specifications. AQL, or Acceptance Quality Limit, represents the quality level that is the worst tolerable in product inspections. Since visual inspection is not 100% reliable, there will be defective products in virtually every production batch. In order to avoid argument, buyers and sellers agree on an AQL standard chosen according to the level of risk each party assumes. This is, then, referenced during pre-shipment inspection. AQL is the limit set between acceptability and refusal in a way that can be agreed upon and measured. AQL tables are statistical tools that buyers utilize for product inspections. Is Quality Built or Inspected Into a Product? We have all seen product recalls for various failures. Whether these recalls are because of hazardous materials or sub-standard parts, they all have something in common: they are not built with quality in mind. These recalls don’t happen because they failed inspection, but because quality was not a part of their foundation and products were quickly pushed out to the public. Quality is built into a product by incorporating quality in the initial specifications, testing to failure, then addressing any flaws until the product performs for the long term. Begin with creating a product that will not only pass inspection, but will also make your consumer happy for as long as possible. Can conducting product inspections help enhance quality? Of course! Having your product inspected before production, during production, and post production prior to shipment will allow for another set of eyes to come in and potentially identify issues early on before something problematic occurs. If issues constantly arise in one of the stages of production, whether with raw materials, during manufacturing or at final packaging, utilization of inspections during these steps will help insure that all issues have been resolved and your product will not end in a disastrous mishap. While quality can’t be inspected into a product, it can definitely help minimize issues reaching your customers. Beginning with quality at the design stage, products that customers want and effective use of inspections, your company will have the opportunity to become an industry leader. Why Quality Matters If you’re wondering whether or not quality should be a top priority in your business, here are some facts to consider: Quality impacts cost. Although this is a given, a product that is well made typically costs more than one that is not; and, when customers are happy with the quality of the item they’ve received, the superb service is not forgotten. Moreover, business is bound to improve. Quality can affect lead times if orders are rushed or realistic lead times aren’t scheduled for production. Quality takes time, and it may very well be worth rescheduling for. Rushing usually causes errors or a subpar execution. Of course your order should be timely, but quality is definitely an important aspect to focus on so as to allow for a smart balance of timeliness and careful handling. Inspections and quality assurance services should be viewed as an investment and not an expense; if a company invests in ensuring that a good product is shipped, then the return is a better quality product on the shelves to sell. The fact is: You get out what you put in. If you spend time and money ensuring that you ship a pristine product, it’s quite likely that your ROI will be high. People want to buy good quality products. It’s as simple as that. Now, let’s focus on the first point and take a deeper look. The Relationship Between Quality and Price What is the relationship between the way a product is priced and its quality? When it comes down to it, there is none. Price doesn’t determine quality. If an item has a high price, that doesn’t necessarily mean it is a high quality product, just as a low price point does not indicate an item is of low quality. This is important information for the end consumer, of course, but it’s also vital for the vendor or importer sourcing products from factories to keep this in mind. Another key thing to note is what the price actually includes. If it seems too good to be true, it probably is. One factory’s low prices may not include the “whole package,” including things like packaging, suitable master cartons, etc. When an importer is solely focused on low prices, they may not get adequate English support, timely follow-up, proper compliance, etc. So, while the price is low and product condition is suitable, the overall product should be considered to be more than just the widget; it is everything the factory provides – and in this case, it is lacking. Think about the overall deal you’re getting in terms of the level of service, efficiency, and everything that’s being provided. If you’re paying a low price but missing key elements, it’s not worth it. If you pay a little more for an all-inclusive package that makes more sense for your business, those are quality products. Don’t tie value directly to a product’s price. There’s much more to the story. The Psychology Behind Price and Quality People are highly susceptible to manipulation, or “priming.” This means that we’re more likely to perceive a low discounted price as equating to good value. A high product price, on the other hand, is typically viewed as an indication of poor value. Whatever is going on in our heads on a given day can impact how we perceive a price, and whether or not we decide to buy something. Words like “bargain” and “deal” tend to spark a more positive reaction than “quality.” But, it’s important to keep in mind that thinking about your success long term will benefit you much more than a quick deal. Buying based on quality means that you’re a forward-thinking professional who values endurance and solidity. Key Takeaway Remember that quality really comes into play when you’re aiming to get the most out of your investment, long term. When you put your customers first, they will, in turn, put you first – and that’s priceless, really. When you build a solid reputation based on satisfaction, your business is bound to thrive.

When deciding which company you should work with, the question to consider is: Which company will be able to meet ALL of your needs? Furthermore, are your products going to serve your customers exactly the way you intend them to? These are important questions to ask yourself because your products represent your brand and your company. If your products are shipped incorrectly or damaged, for example, that reflects negatively upon your business. Another big question to consider: Is your product really as good as you advertise it to be? Utilizing during production inspections and post-production inspections ensures the quality of your company’s products. Rather than merely crossing your fingers and hoping for the best, you need to monitor that everything is under perfect control. That’s exactly where third party quality assurance services come into play. Inspections are crucial to your company's success – as are Lab Testing Services, where it is determined whether or not the product meets international standards, to ensuring that your vendor follows requirements, to training and consulting services. Executing these quality assurance services on a regular basis is a key component of any successful company. How Needs Are Changing & Growing Are you happy with how your needs are being met by your current provider but not sure if their services are robust enough to support your growth? As your company grows, your service needs may expand as well. In the early stages of a company, an inspector may only be needed once or twice every month. Additional services can become necessary when your company gains traction in it’s specified field. Have you found that your company needs full time inspection resources? If this is true, you might consider training an internal employee full time on quality inspection services. You will find that hiring a full time inspector will help you achieve efficiency, timeliness, and better quality products within your expanding company. What Are Your Needs? Third party companies offer a variety of services. That being said, you should focus on the specific services that best apply to your business. How do you know if you need pre-shipment inspections or assistance with C-TPAT? Are there environmental factors that need to be taken into account? There are many important details to keep in mind. Key Considerations for Inspection Before Delivery: It is crucial that you know what is being shipped from your suppliers. Testing your products before the inspection process will help minimize the risk of importing unsuitable merchandise. Do you need Social Accountability Audits, Security/C-TPAT Assessments, Factory Quality, or Capability and Capacity Assessments? If you want to minimize product recalls, ensure quality production, and a stable workforce, the answer is yes If your company has safety requirements for its products, there is increased risk. You need to make sure these requirements are met before the products are shipped. Knowing that your products are shipped exactly the way they were intended is the last step in guaranteeing a successful product shipment. Not every third party service provider assists companies with everything from A to Z. Some ONLY perform product inspections, some ONLY assist with logistics. You may need the full package as opposed to specific services. Truly understanding your company's needs is key to choosing a service provider that meets your requirements. The safety of a customer who is receiving products is always on the minds of suppliers, manufacturers and producers. Within the last couple of years, safety regulations were put in place not to just reduce the potential for injury to consumers, but also to protect retailers. Does your product have a liability associated with it? If so, you need to take precautions to minimize those potential liabilities. Not just safety requirements. Training and consulting your own staff may also help address potential problems. What Could Go Wrong? A Lot. Needs are growing and changing every day. This requires businesses to maintain flexibility and adapt to these changes as well. If your products fail to meet federal labeling requirements, they are required to be permanently labeled with a safety statement. Also, if death or harm occurs to your consumer, lawsuits can arise. In today’s marketplace it is vital to consider social and ethical compliance. It’s all about the people who contribute to your company’s success. That is why it is necessary to inspect workplace health and safety, wages, working hours, and possible discrimination. Corporate social responsibility is increasingly playing a role in consumer decisions. Quality Fade: When companies start out supplying high quality products, but start cutting corners in alarming ways.

For consumer goods importers, screening a new supplier takes a significant amount of time and energy. Whether you’re deciding to move away from a current supplier or you’re choosing a supplier for the first time, it is important not to rush the process. A hasty decision can lead to lower product quality. And a bad reputation or poor product reviews can be difficult to bounce back from. A factory audit is a tool that will help you make the best possible decision for your situation. It aids you in determining whether a manufacturer is actually capable of meeting the needs of your organization. And you want to know that they can do what they say they can do. Below we’ll provide a downloadable audit template, designed to assess a supplier’s quality systems. A factory audit can be tailored to meet your specific needs, for example, with a focus on environmental friendliness, social responsibility, security, or other concerns. Sections might be added or subtracted, as needed. Let’s talk about the different things we generally look at and the sections included in the standard quality audit. Section #1: Facilities The first section of the assessment focuses on facilities. Is the plant layout generally acceptable? Is overall maintenance of the premises acceptable? Does the general housekeeping appear acceptable? These and other questions are asked to get an understanding of the layout and circumstances at the facility. Section #2: Quality Control System Next, we focus on the supplier’s quality control system. Do they appear to have a formal internal quality control program in place? Is there a formal training program for QC personnel? Do they have a complete quality manual? Asking questions like these helps give us an idea of whether they will produce your products to the quality standards you expect. It helps identify what kind of system they have in place and whether it is being followed. Section #3: Incoming Materials Inspections The third section focuses on incoming materials. Is the supplier taking measures to assure raw materials conform to specifications? Are materials properly labeled, stored, and traceable? Are they kept in controlled storerooms to avoid theft, loss, and deterioration of quality? The key thing here is that the factory has processes in place so that they can avoid using the wrong materials (whether plastic, metal, or wood). It’s also important that materials are free of harmful substances. Section #4: In-Process Quality Control After incoming materials, we take a look at in-process quality control. Are samples for the pilot run carefully reviewed by engineers and quality managers? Is the QC staff well trained and are there enough QC employees to meet the needs of mass production? Are international standards used to carry out in-process inspections? Having proper quality control measures in place during the production process allows them to identify issues early so that they don’t become a bigger problem later. After the factory’s initial internal inspection, a third-party inspection should be conducted in a similar manner. Section #5: Final Inspection Aside from in-process inspections, the manufacturer should also conduct final inspections. Does the quality control staff perform an internal final inspection of merchandise? Are international or other approved standards used? Are written formal inspection reports properly filed and traced to review the quality of products? Asking these kinds of questions helps you determine how diligently a factory is checking their final products. This way, they can ensure your orders ship as defect-free as possible. Section #6: Packaging The next thing to think about is packaging. Is the packaging area clean, well organized, and free of contaminants? Are there safeguards in place to prevent the wrong products from going into the wrong packaging or master cartons? Do workers wear gloves or other protective clothing to avoid contamination, if necessary? It is important that products be free of dust and dirt, are stored so that they aren’t affected by sunlight or moisture, and have all the appropriate shipping marks and date codes on them. Section #7: Non-Conforming Materials Another concern for importers is non-conforming materials. Are non-conforming materials or products being properly identified and segregated at all stages of production? Is scrap metal handled satisfactorily? Is the overall policy of treating non-conforming materials effective? These types of questions are important because products can pick up defects on their way through the manufacturing process. They should be separated out as soon as possible to ensure the quality of each purchase order. Section #8: Communication, Documentation, Control, and Work Movement The eighth section focuses on communication, documentation, control, and work movement. Do factory management and key staff understand and speak English sufficiently to enable direct communication with customers? Is there an adequate and formal system for receiving purchase orders, tooling, and equipment? What about a system for receiving and applying drawing, procedural, or design changes correctly? Depending on your business and your communication requirements, different things may be necessary. But, in general, smooth communication is important. Section #9: Handling of Complaints The handling of complaints is another key thing we look at. Are customer complaints handled by management? Does the factory have a formal process for handling customer complaints? Are complaints analyzed for their root causes? Knowing that the supplier has a clear process for handling complaints and that it is documented ensures that customers are truly being listened to. These processes for handling feedback are essential. Section #10: Total Score Based on the scores of all the previous sections, a total score should be calculated. Certain sections have a higher weight than others, but this can be customized according to your needs. We sometimes add in additional environmental, social compliance, security-related, or other sections and tailor the weighting of each section to your needs.